Custom Jewelry & Wedding Rings

Jewelry That Begins With Your Story

At JC Jewelers, custom jewelry is at the heart of what we do. Our Jackson Hole studio specializes in creating custom made jewelry that reflects your vision, your values, and the moments that matter most. Whether you’re dreaming up a one-of-a-kind engagement ring, designing a piece to celebrate a milestone, or bringing new life to heirloom stones, we are honored to be part of your journey.

Our Custom Jewelry Process

We partner with you from the first spark of an idea to the moment your piece arrives — crafted with intention and care, every step of the way:

Sketch

We begin with hand-drawn ideas during our initial consultation. These sketches help us capture the emotion behind your vision and lay a foundation for the design.

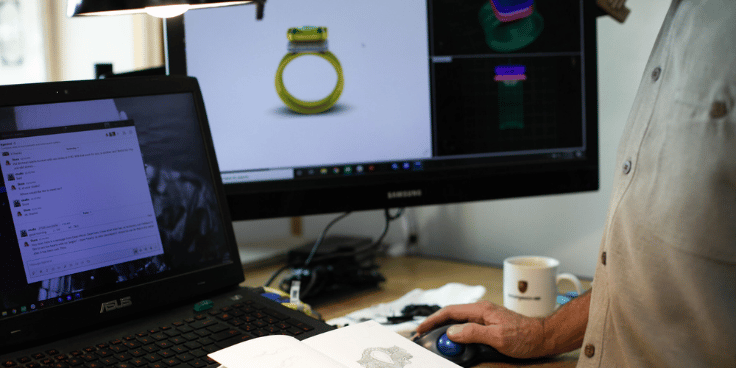

CAD Design & 3D Modeling

Next, we translate your sketch into a detailed digital model using CAD software. This step lets us visualize every angle and fine-tune proportions before moving forward.

Wax Prototype & Casting

A physical wax or resin model is produced — often via 3D printing — so you can see and feel your design in real form. Once approved, we use the lost-wax casting method to bring the final piece to life in precious metal.

Finishing & Final Product

After casting, each piece undergoes careful stone setting, polishing, and quality control. Our team performs the final touches — smoothing, shine, and structural checks — until your piece is showroom-ready.

Your Stories, Our Craft

Our custom jewelry design process is collaborative, creative, and personal — from the first sketch to the final polish. Using CAD/CAM modeling, 3D printing, and laser repair technology, we bring even the most intricate ideas to life. As a trusted custom jewelry maker, we work in platinum and gold, ensuring every detail meets our highest standards of craftsmanship and care.

We’ve designed everything from bold contemporary wedding rings to delicate bands that complement vintage pieces. Highlights of our portfolio include custom diamond jewelry set with rare sapphires, flawless diamonds, and stones with deep personal meaning.

Don’t know if your idea requires full custom work? We also offer in-house repairs and modifications through a network of expert vendors — all with the same level of attention and transparency.

Whether you’re local or exploring custom jewelry online, JC Jewelers is here to bring your vision to life with integrity, artistry, and joy.

Let’s create something beautiful — together.